| Search for content and authors |

Diamond-tungsten carbide nanocomposite |

| Sergii Nazarchuk 1, Oleksand Bochechka 1, Stanisław Gierlotka 2, Igor Dzięcielewski 2, Mykola Gadzyra 3 |

|

1. V. Bakul Institute for Superhard Materials of the National Academy of Sciences of Ukraine (ISM), 2, Avtozavodska Str., Kyiv 04074, Ukraine |

| Abstract |

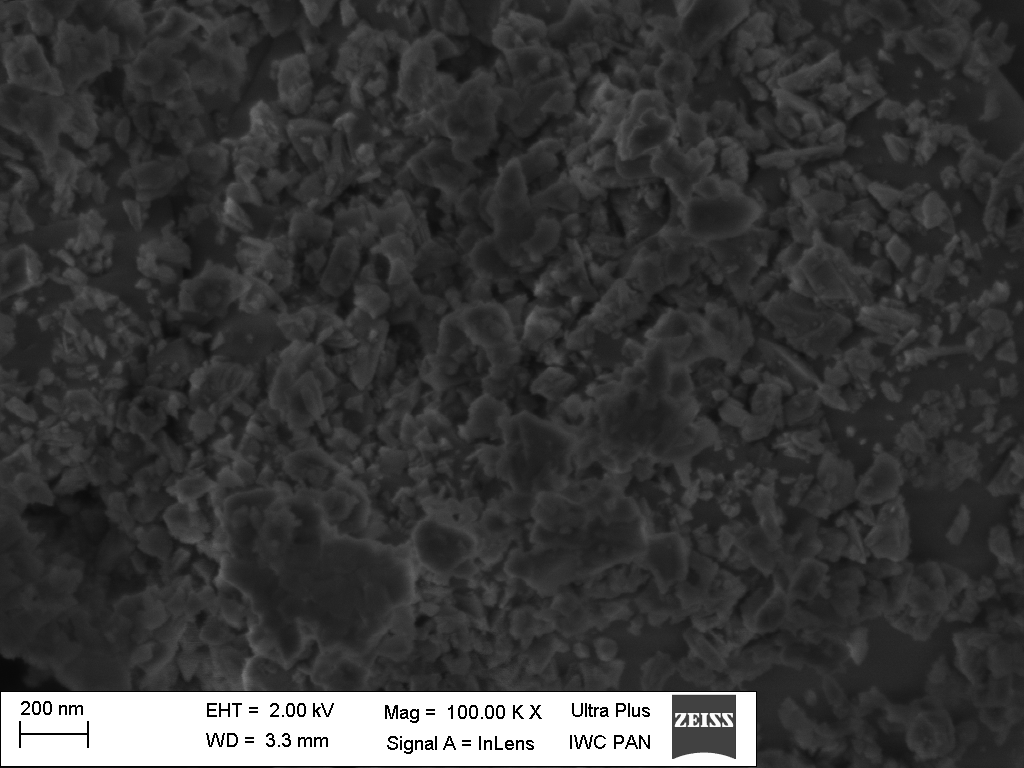

Nanopowder mixtures of ASM5 0.1/0 diamond, and WO3 were formed in the liquid. Air drying and thermal treatment of these mixtures in hydrogen were carried out. Composites were HP sintered from them [1, 2]. The structure and phase composition of the mixtures and sintered composites have been studied. The WO3 particle size is in the range of 150–250 nm, the particles are fragmented, the grain size varies from 10 to 150 nm. The size of the diamond particles does not exceed 100 nm. The relative position of the particles of diamond and WO3 is homogeneous enough, however, a tendency to agglomerate particles is observed (fig. 1).

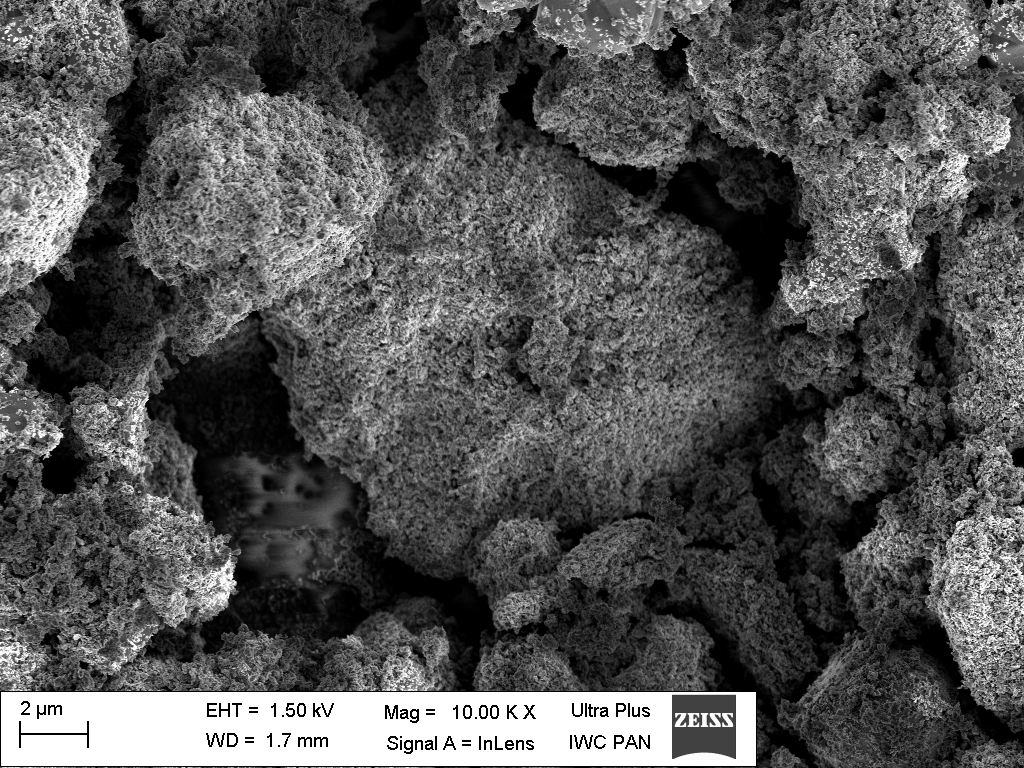

Fig. 1. The structure of the mixture of ASM5 0.1/0 statically synthesized diamond nanopowder and tungsten trioxide powder (46%) formed in a liquid after drying before annealing in hydrogen During the mixture heat treatment in hydrogen at the temperature of 900 °C the complete recovery of WO3 to the metal tungsten occurs. In case of deviation from the heat treatment the W3O oxide is present in the mixture, together with metallic tungsten and WO2. The particle size of formed tungsten increased by 2–3 times compared to the WO3 precursor particles (fig. 2). The formed particles are less fragmented.

a

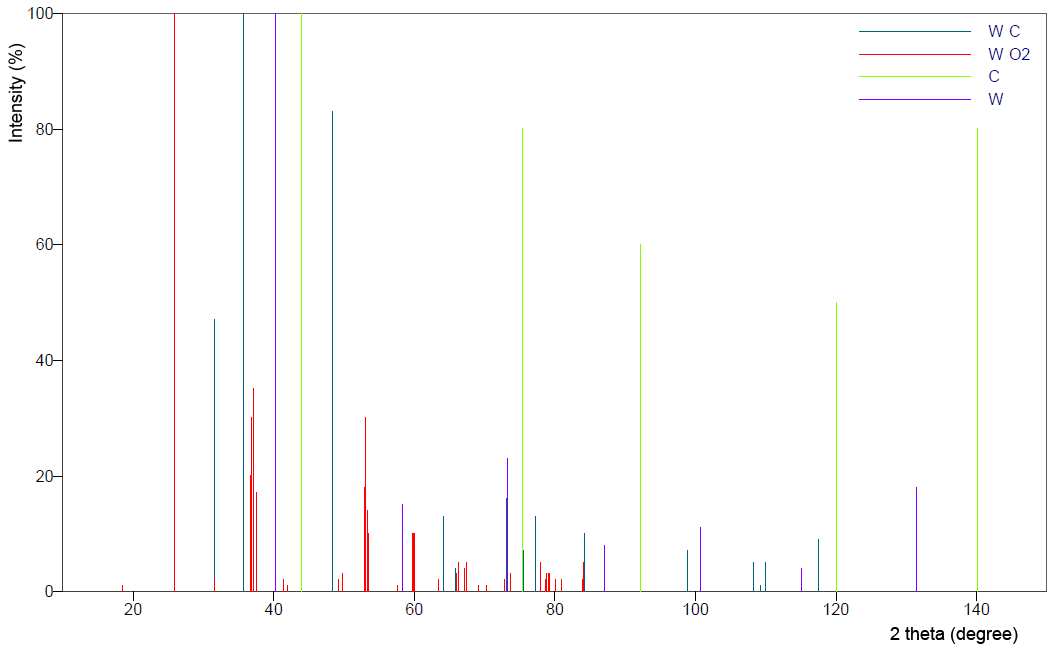

b Fig. 2. Structure of the mixture of diamond nanopowder and tungsten trioxide after annealing in hydrogen obtained by SEM at different magnifications (a, b) The diamond and WC are the main phases in the composite sintered from the mixture which includes WO2, apart from diamond and tungsten. A small amount of W and WO2 is also present. Amount of WO2 has not changed compared to the initial mixture (fig. 3). WC formed as a result of the diamond and tungsten reaction is in the interspaces between the diamond particles and improves the connection between them (fig. 4). While the presence of WO2 in the interspaces worsens the connection.

b Fig. 3. Diffractogram (a) and diffraction pattern (b) of composite sintered from a mixture of diamond nanopowder and tungsten powder treatment in hydrogen

Fig. 4. The structure of the surface obtained by shearing the sintered composite sample

|

| Legal notice |

|

| Related papers |

Presentation: Poster at Nano and Advanced Materials Workshop and Fair, by Sergii NazarchukSee On-line Journal of Nano and Advanced Materials Workshop and Fair Submitted: 2013-06-07 14:42 Revised: 2013-06-10 13:01 |