| Search for content and authors |

VGF Growth of CdTe Crystal Assisted by Axial Vibration Control Technique Under Controlled Cadmium Pressure |

| Igor C. Avetissov , Andrey P. Sadovskiy , Mikhail Grishechkin , Vladimir Meshkov , Andrew Khomykov , Vladimir Kostikov , Ekaterina Sukhanova , Elena Mozhevitina |

|

D.I.Mendeleyev University of Chemical Technology of Russia (MUCTR), Miusskaya sq. 9, Moscow 125047, Russian Federation |

| Abstract |

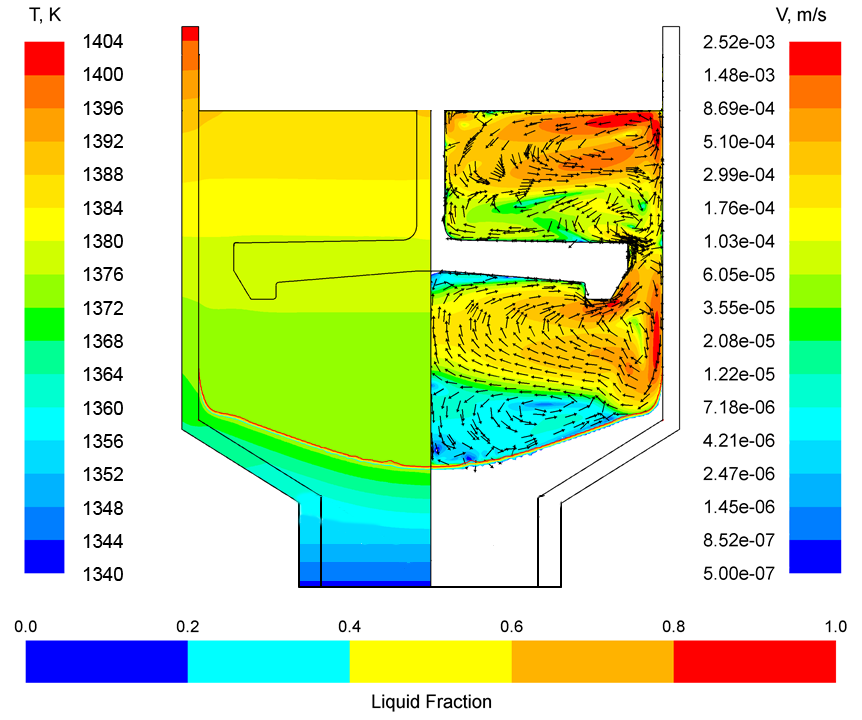

Axial Vibrational Control (AVC) technique is a powerful tool for conrol of convective flows (CFs) in the melt with desirable velocity and configuration. In Czochralski and Brigdman crystal growth the AVC technique was realized by axial low-frequency harmonic oscillation of an inert baffle submerged into the melt [1, 2]. An application of low-frequency vibrations made it possible to increase in several times crystal growth rate [2], to decrease dislocation density up to unit value [3], to enhance crystal perfection [4,5]. It was experimentally established that AVC efficacy based on melt structure transformation [6]. All these open perspectives for successful invention of AVC technique to other scheme of crystal growth. Taking into account an intensive mixing of the melt and leveling of component concentrations at application of AVC technique we demonstrated the efficiency of partial pressure control at CdTe crystal growth [7]. CdTe has very low thermal conductivity and it is difficult to withdraw the crystallization (latent) heat in case of large diameter crystal growing with a fast rate. Numerical simulation showed that solid "tails" were formed at seeded VFG growth of 50 mm diameter CdTe crystals (Fig.1). AVC application with specially configured oscillating disk let us dissolved the "tails" and supported a flat interface at comparatively high growth rate (Fig.2). Fig.1. Numerical simuletion of crystl-melt interface position at CdTe VGF crystal growth at 5 k/cm gradient and 5 k/h crystallization rate.

Fig.2. Mean flow velocity (right) and static temperature (left) maps at the baffle oscillation at 25 Hz frequency and 0.25 mm amplitude with solidification contours near crystal-melt interface at CdTe VGF crystal growth at 5 k/cm gradient and 5 k/h crystallization rate.. We designed and made a VGF setup assisted by AVC unit and possibility to control cadmium partial pressure using van-Doorn technique [8] (Fig.3). CdTe crystals were grown at different Cd partial pressure and their electrical properties, structure perfection, impurities and nonstoichiometry distribution both cross-section and longitudal were analyzed. We succeeded to control the crystal type (n,p) by varying Cd pressure from 0,2 to 3 atm at different growth processes. The research was supported by Ministry of Education and Science of Russia by grant N 16.552.11.7046. [1] I. Avetissov et al. Doklady Physics, 54, N. 9, 410 (2009)

Fig.3 Scheme of CdTe VGF crystal growth setup. 1- thermo insulating stand, 2- graphte rings, 3- saphire heat removal cylynder, 4- seed, 5- crystal, 6- melt, 7- graphite vibrating baffle, 8- vibrating graphite rod, 9- Cd melt drops capture plates, 10- plate resistive heaters with ceramic, 11- heater lead-out wire, 12- thermo insulation, 13-graphite reactor, 14- thermo insulating plug, 15- vibrator |

| Legal notice |

|

| Related papers |

Presentation: Poster at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, Topical Session 4, by Igor C. AvetissovSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-03-13 21:31 Revised: 2013-07-26 10:04 |