| Search for content and authors |

The effect of process parameters on floating zone crystal growth of selected cuprates |

| Nadja Wizent 1, Patrick Ribero 1, Günter Behr 1, Wolfgang Löser 1, Rüdiger Klingeler 2, Bernd Büchner 1 |

|

1. Leibniz-Institute for Solid State and Materials Research, P.O.Box 270116, Dresden D-01171, Germany |

| Abstract |

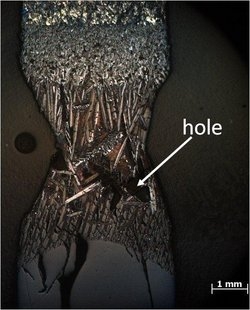

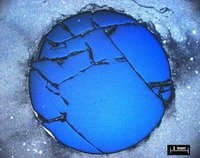

Single crystals of cuprates are unique subjects of fundamental research because of their high-Tc superconducting properties but also as excellent model systems for low-dimensional quantum antiferromagnetism. Here the crystal growth of selected cuprates by the floating zone (FZ) method with optical heating is analysed. Two different FZ facilities with vertical double ellipsoid optical configuration were primarily applied because of the radial symmetry of light flux and sharper focussing of the light leading to a steep temperature gradient at the crystal/melt interface. The compact growth chamber enables high gas pressure up to 15 MPa. Process parameters for FZ crystal growth principally depend on the constitution of the systems. In case of congruent melting compounds, such as Li2CuO2, a growth velocity of 10 mm/h has been reached. In this case, the elevated total pressure of 50 bar of a gas mixture of Ar:O2 4:1 has minimized the vaporization of the volatile element Li and prevented the crystallization of a secondary phase. Cuprates with incongruent melting behaviour were grown with the travelling solvent floating zone (TSFZ) method at low velocities of the order of 1 mm/h or less. Because of the considerable composition difference at the crystal/melt interface steep temperature gradients and counter-rotation of crystal and feed rod are favourable for suppressing constitutional supercooling. Often phase diagrams of the cuprate systems are not precisely known. Phase equilibria were analysed by quenching the ultimate zone after the growth process (Fig.1). The floating zones in TSFZ growth of multicomponent cuprates are not only enriched in CuO, but display diverse other element segregation. In TSFZ growth of the Nd2Ca2Cu5O10 crystal (Fig. 2), depletion of Ca and Nd in the solvent was revealed. For Ca2+xY2-xCu5O10 even liquid phase separation was detected in the floating zone where the crystal grew from a Y-depleted melt contrasted by the Y-rich melt adjacent to the feed rod. Oxygen is a main constituent of the cuprates, and therefore the ambient atmosphere in the growth chamber affects the thermodynamic equilibria. Because copper can change its valence state, oxygen is often released on melting of cuprates whereas crystallization requires oxygen uptake. The TSFZ process proceeds with oxygen depleted melt zone. Elevated oxygen pressure up to 15 MPa can alter the solidification mode towards congruent melting [2], which is beneficial for achieving higher growth rates. It even enables the crystallization of novel compounds not stable at normal pressure, e.g., Sr14-xCaxCu24O41 compounds with high Ca fractions x > 12. By using O2/Ar gas mixtures, the oxygen partial pressure in the growth chamber can be controlled independently. Harmful formation of gas bubbles in the floating zone is diminished, which often arises in growth at high oxygen pressure (cf. Fig. 1).

Fig. 1. Quenched last zone between feed rod (top) and Nd2Ca2Cu5O10 crystal (bottom).

Fig. 2. Cross section of Nd2Ca2Cu5O10 crystal grown at oxygen pressure 4 MPa and v = 2 mm/h [1]. The control of the temperature profile, stable FZ geometry and a proper crystal/melt interface shape are other necessities for the TSFZ process. In the vertical crystal growth apparatus the irradiation profile is modified by the lamp position, but by higher rotation rates of the seed via melt convection the interface shape can also be flattened. In TSFZ growth of some cuprates spikes of refractory phases often crystallize at the surface of the partially melted feed rods. This is caused by grazing rays close to the optical axis, which must be eliminated from the incident light flux by a light blocker. [1] N. Wizent, Thesis, TU Dresden 2009. [2] N. Wizent , L. Schramm, G. Behr, W. Löser, W. Gruner, A. Voß, B. Büchner, L. Schultz, J. Solid State Chem. 182 (2009) 2036–2040. |

| Legal notice |

|

| Related papers |

Presentation: Oral at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, Topical Session 1, by Wolfgang LöserSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-03-28 11:22 Revised: 2013-07-23 17:16 |