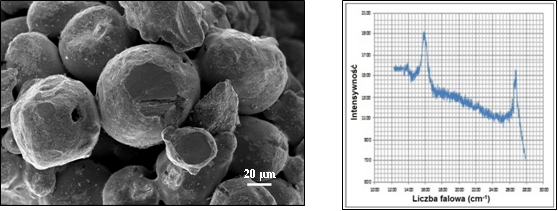

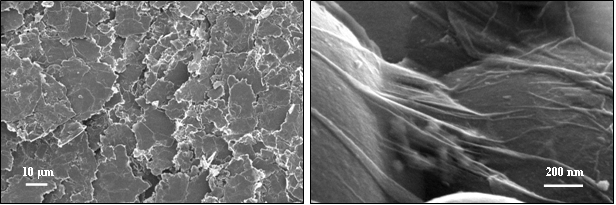

The Institute of Precision Mechanics developed CarboTermoFluid® technology for producing graphene on the grains of powder which is called Graphene 3DIMP. This technology can produce graphene on powders of metals and non-metals of different geometry and size of powder grains. Graphene formed on the copper powders can be used to manufacture: electrical contacts with high thermal and electrical conductivities, transmission cables, heat exchangers, radiators, bearings, lubricants, and pastes. Identification of the formed graphene 3DIMP was performed by using Raman spectroscopy and scanning electron microscopy (SEM). Image of Cu grain coated with graphene 3DIMP and Raman spectrum of graphene are shown in Fig. 1 and Fig. 2, respectively.

| Fig. 1. Cu grain coated with graphene 3DIMP |

Fig. 2 Raman spectrum of Graphene 3DIMP |

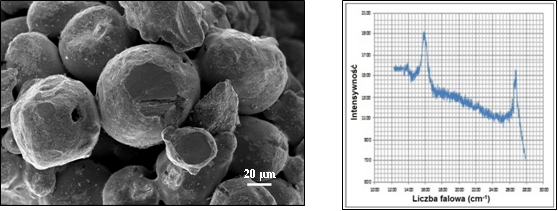

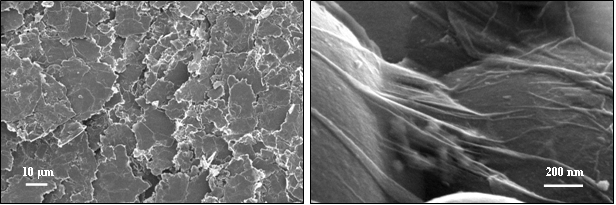

In parallel, in the Institute of Precision Mechanics are manufactured metal/graphene nanocomposite layers by chemical and electrochemical reductions. The nanocomposite layers of Ni-P/graphene, Ni/graphene, Cu/graphene are characterized by nanocrystalline and compact structures as well as good adhesion to the substrate. The structure and properties of the metal/graphene nanocomposite layers were investigated by: scanning electron microscopy, EDS analysis, optical microscopy and the measurement of HV microhardness. Inclusion of graphene into a metal matrix significantly improved thermal and electrical conductivities as well as mechanical properties of such layers. SEM images of graphene flakes and of layer surface of Ni-P/graphene composite are shown in Fig. 3 and Fig. 4, respectively.

| Fig. 3. SEM image of graphene flakes |

Fig. 4. Surface of the Ni-P/graphene composite layer |

|