| Search for content and authors |

Czochralski growth of R2TSi3 single crystals |

| Maria Szlawska , Dariusz Kaczorowski |

|

Institue of Low Temperature and Structure Research, Polish Academy of Sciences (INTIBS-PAN), P.Nr 1410, Wrocław 50-950, Poland |

| Abstract |

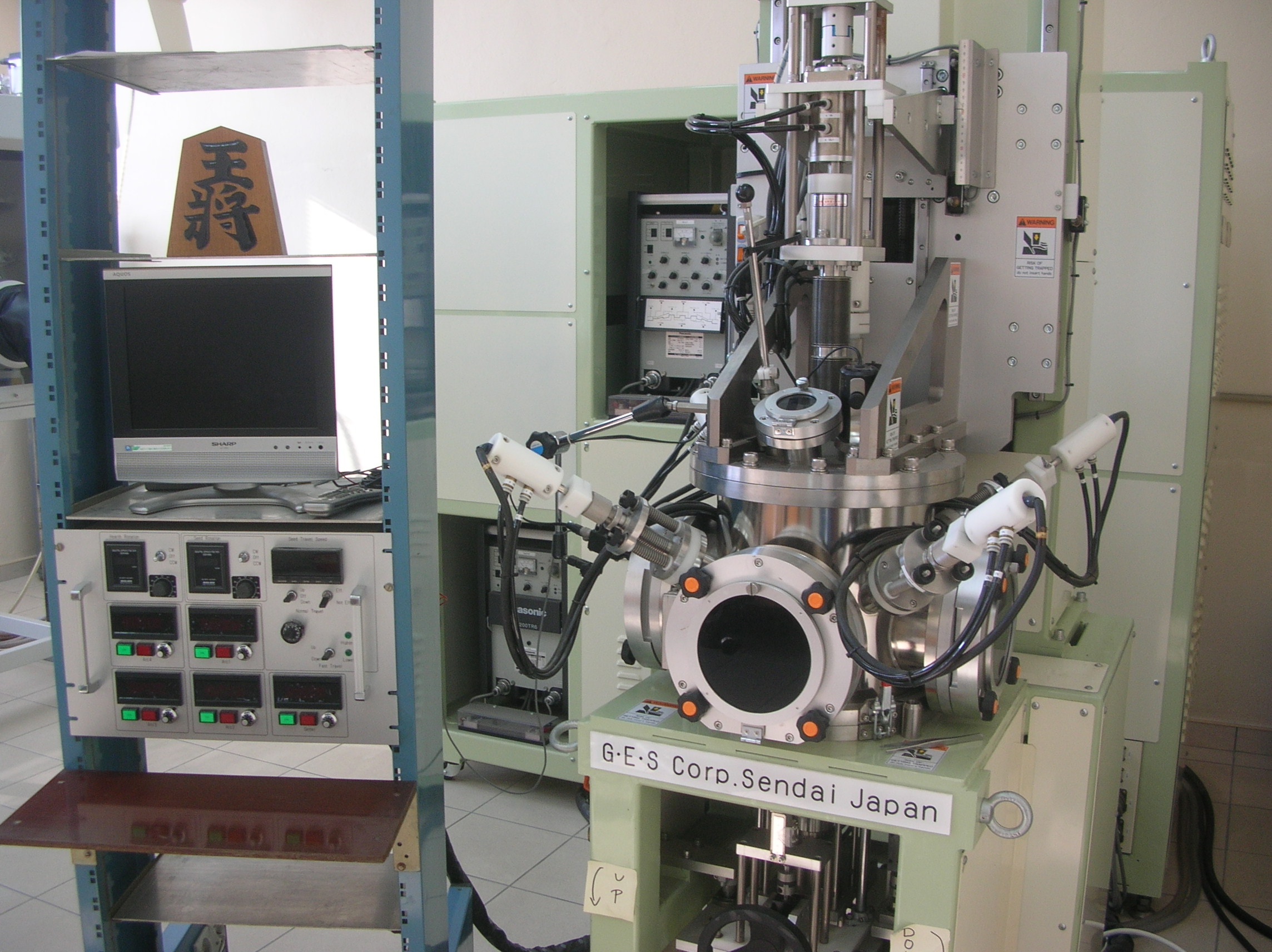

| The Czochralski process of crystal growth, named after Polish scientist Jan Czochralski, who invented the method in 1916 while investigating the crystallization rates of metals, is used in the semiconductor industry for the purpose of obtaining large single crystals of silicon with low density of defects. Application of the technique has induced technological revolution that led to advanced electronic devices being nowadays in common usage. The Czochralski technique is also widely employed in the area of fundamental research, as advanced studies on well-defined high-quality single crystals are indispensable for gaining important information on the physical properties of novel materials, which cannot be inferred from analogous characterization carried out on polycrystalline specimens. Most of the Czochralski furnaces used in industry and in research laboratories utilize high-frequency electric induction heaters or resistance heaters to melt substrate. Their fundamental disadvantage is the presence of a hot crucible that may contaminate the grown material, especially if the latter has a high melting point. This problem is absent in cold-heart-type furnaces, which employ electric arcs ignited between tungsten-made cathodes and a water-cooled copper anode that serves as a crucible. Usually, three or four electric arcs are being lit and slow rotation of the heart is applied in order to provide uniform heating of molten material. The Czochralski furnace installed at the Institute of Low Temperature and Structure Research, Polish Academy of Sciences in Wrocław (see the photograph on Fig. 1) is one of very few tetra-arc pulling furnaces available worldwide, and to the best of our knowledge the only one in Poland. Since its delivery from Japan in 2006,

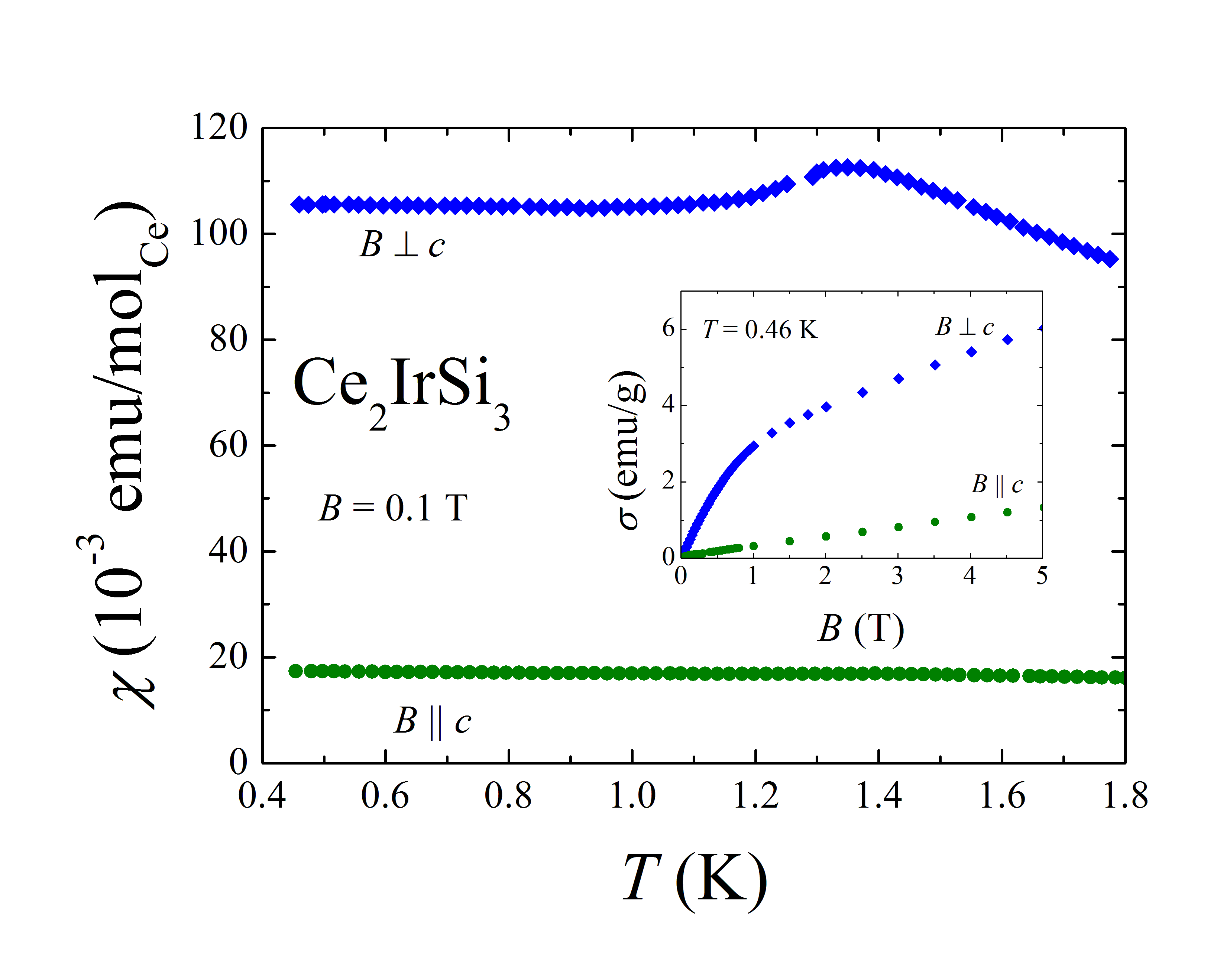

Fig. 1. The tetra-arc Czochralski furnace installed at the Institute of Low Temperature and Structure Research, Polish Academy of Sciences in Wrocław. it has been successfully used to grow numerous excellent quality single crystals of various intermetallic compounds, with a special focus on cerium- and uranium-based ternaries. As 4f- and 5f-electron based phases usually melt at rather high temperatures, yet possess relatively low vapor pressures and many of them melt congruently, using this type of Czochralski technique seems to be the best way of obtaining well developed crystals. They have a shape of cylindrical rods with a diameter up to 3-4 mm and typical length of a few dozen mm. Among the many compounds obtained to date in our Crystal Growth Laboratory in the form of excellent-quality single crystals, there is a series of ternary silicides with the overall composition R2TSi3, where R = Ce, U and T = Ni, Co, Rh, Ir. These phases crystallize with hexagonal disordered AlB2-type structure (space group P6/mmm) or its more or less ordered derivatives. In the parent-type unit cell, R atoms occupy Al position and form triangular planar networks, while T and Si atoms share B site. Such arrangement of atoms inherently introduces frustration and randomness of exchange interactions between magnetic atoms, which may result in highly unusual magnetic properties. As an example, Fig. 2 displays a Czochralski-grown single crystal of Ce2IrSi3, which was recently comprehensively investigated by means of X-ray diffraction, magnetic, electrical transport and heat capacity measurements, performed in wide ranges of temperature and magnetic field strength [1,2]. The compound was found to form with a fully-ordered unit cell, which is doubled within the basal hexagonal plane with respect to the parent AlB2-type substructure. As can be inferred from Fig. 3, it orders antiferromagnetically at TN = 1.3 K with the magnetic susceptibility taken within the ab plane, χab, being distinctly larger than that measured along the c axis, χc. Remarkably, the latter component hardly shows any anomaly at TN. A distinct magnetic anisotropy is observed also in the field dependencies of the magnetization measured deeply in the ordered state (see the inset to Fig. 3). The component σc is roughly proportional to B, while that taken within the ab plane has much larger values and σab (B) is strongly curvilinear. These results concomitantly indicate that the magnetic moments in the compound studied are probably confined to the basal hexagonal plane. The long-range antiferromagnetic ordering in Ce2IrSi3 is accompanied by strong

Fig. 2. A single crystal of Ce2IrSi3 grown by Czochralski technique in the tetra-arc furnace.

Fig. 3. Temperature variations of the magnetic susceptibility of single-crystalline Ce2IrSi3, measured in the magnetic field of 0.1 T oriented parallel and perpendicular to the c axis of the hexagonal unit cell. The inset presents magnetic field variations of the magnetization measured at 0.46 K.

electronic correlations effects, which manifest themselves in an enhanced low-temperature linear contribution to the specific heat, large negative values of the paramagnetic Curie temperatures, as well as in clear negative logarithmic slopes in the electrical resistivity. Based on all the experimental findings, Ce2IrSi3 can be categorized as an antiferromagnetic Kondo lattice with a moderate-heavy fermion ground state.

[1] M. Szlawska, D. Kaczorowski, Phys. Rev. B 84, 094430 (2011) [2] M. Szlawska, D. Kaczorowski, to be published in J. Korean Phys. Soc. |

| Legal notice |

|

| Related papers |

Presentation: Oral at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, Topical Session 1, by Maria SzlawskaSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-04-08 10:21 Revised: 2013-07-08 14:55 |