| Search for content and authors |

Intervertebral disc endoprosthesis – structure, tests, production technology and preparation for clinical applications |

| Adrian Mróz 1, Konstanty Skalski 2, Marcin Lijewski 1 |

|

1. Instytut Obróbki Plastycznej (INOP), ul.Jana PawłaII14, Poznań 61-139, Poland |

| Abstract |

| Full title of the project: Intervertebral disc endoprosthesis – structure, tests, production technology and preparation for clinical applications

Name of the program: Development Project of the 10th Competition Application year: 2009 Realization years: 2010-2013 The list of key parameters of the project:

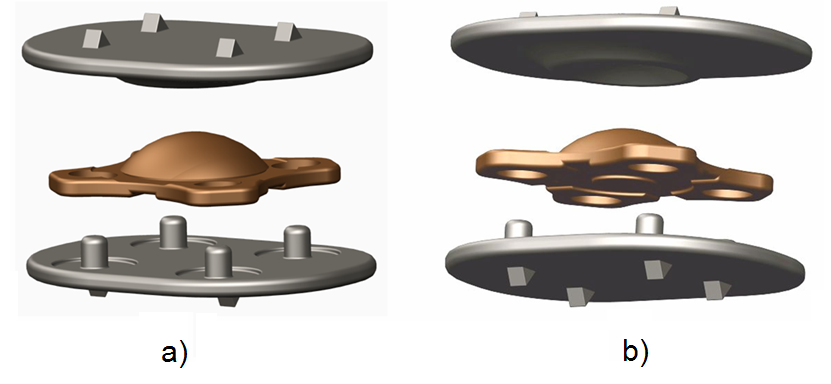

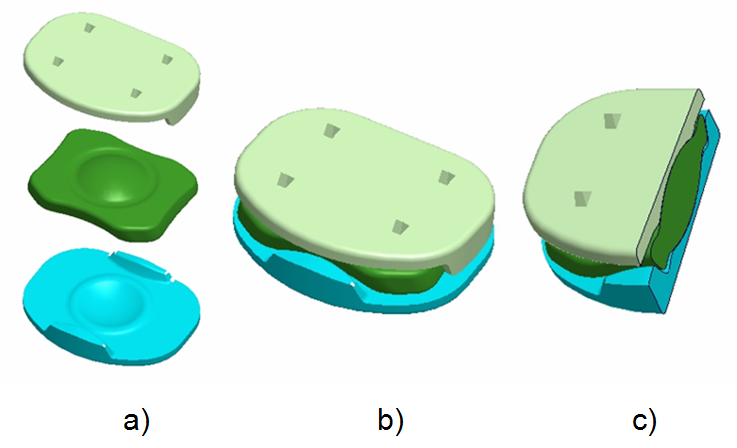

The objective of the project includes preparation of the structure and production of clinical prototypes of an intervertebral disc endoprosthesis for clinical applications. The scope of works conducted includes identification of characteristic (anatomical) features of the muscle-skeleton segment of the spine in various individuals with the use of CT and MRI as well as preparation of methodology of parametrical designing of the intervertebral disc endoprostheses. A relevant trend of works under the realized project includes optimization of the intervertebral disc endoprosthesis production process and production of prototypes of an intervertebral disc implant for tests on animals and clinical evaluation. During realization of the project they prepare technical documentation in the form of parametrical 3D models and 2D drawings as well as technological processes for production of physical models (one of the generative techniques) and production of prototypes with the use of CNC machines. The project includes designing of two independent three-element structures of the lumbar intervertebral disc endoprostheses: INOP/LSP.1101 (Fig. 1) and PW-BSZ (fig. 2) [1, 2]. Owing to appropriate selection of geometrical parameters, each of the structures is to reflect operation of a natural disc. By complying with requirements relating both to reflection of movement in L4-L5 spine segment as well as correct connection with intervertebral bodies, they show anatomical functional properties (custom design). Moreover, use of mobile inserts ensures variability of position of the rotating axis during operation of the endoprostheses and, thus, better reflection of natural disc kinematics [1]. Positive verification of the selection of the geometrical and ergonomic features of endoprostheses and satisfactory results of the numerical strength analyses of the implant-bone couple allowed a commencement of production of technical prototypes. The prototypes were made of materials used successfully for implants – cobalt based alloy (Co28Cr6Mo), titanium based alloy (Ti6Al4V) and nickel-free austenite steel (316L) with the use of three various technologies (fig. 3). Endoprostheses of Co28Cr6Mo and Ti6Al4V alloys were made with the use of CNC machines. Endoprostheses components were made of Co28Cr6Mo and Ti6Al4V alloy powders with the use of Selective Laser Melting technology. 316L steel forgings were made with the use of gear forging method and, then, subject to CNC machining. The quality of friction surfaces after polishing was characterized by the Ra roughness below 0.05 μm.

Fig. 1. INOP/LSP.1101 endoprosthesis – components: a) anteverted, b) retroverted [3]

Fig. 2. PW-BSZ endoprosthesis: a) components, b) anteverted endoprosthesis, c) cross-section in the sagittal plane

Fig. 3. INOP/LSL.1101 endoprosthesis components made of various materials with the use of various technologies, the condition of surface after polishing: a) upper plate, CoCrMo alloy, CNC machining, b) insert, 316L steel, CNC machining following gear forging, c) bottom plate, Ti6Al4V alloy, SLM technology An endoprosthesis implanted in the human organism should be characterized by biocompatibility and high durability in order to fulfill its functions properly. The durability of presently used endoprostheses is limited due to friction between the cooperating components. In order to verify the applied production technologies activities aimed at friction and wear tests of a selected endoprosthesis structure were undertaken. The verification included:

The object of friction and wear tests constitutes six sets of INOP/LSP.1101 endoprostheses. Three of them were made of Co28Cr6Mo alloy through machining. Another three were made with the use of SLM technology and Co28Cr6Mo powder. Each of the endoprostheses worked on the simulator for 1 000 000 cycles. The friction loop was loaded with a force of maximum instantaneous value of 1500 N. The swiveling angle of the upper plate for bending was: +8o, the swiveling angle for hyperextension was: -5o. The one-sided angle of axial twisting was: ± 3o. The frequency of movement was 1.25 Hz. The tests were conducted in a distilled ultraclean water environment (fig. 4).  Fig. 4. A view of the simulator for the testing of spine implants [4, 5] Fig. 4. A view of the simulator for the testing of spine implants [4, 5]

Results of friction and wear tests showed that, regardless of technology used, the value of friction coefficient in the tribological system of the tested endoprostheses was similar and on average amounted to 0.278 (±0.013) for CNC and 0.273 (±0.019) for SLM. However, the wear processes in SLM were more intense. This is proved by the mass wear values. The average mass wear of the CNC endoprostheses amounted to 19.2 mg, whereas for SLM endoprostheses the mass wear decrease was 25.5 mg. Greater wear of the SLM components is reflected in the roughness of the friction surfaces. For example, the average roughness of the inserts made with the use of CNC method upon completion of the tribological tests was 1.07 μm, whereas the Ra roughness of the SLM insert was characterized by the average roughness of 1.14 μm. The main objective of the Project is preparation of the structure and production of an intervertebral disc endoprosthesis prototypes used for clinical applications and complying with the license requirements of the European Union. It is highly probable that the project will contribute to the introduction of a new and competitive product into the market and formulation of a business policy based on identification of market and social demands as regards the improvement of human functions in the society, vocational and physical activities as well as economic aspects. The area of advanced technologies clearly determines the horizontal policy, guidelines of the European Union and national strategic and research programs. One of the priorities of the National program for Scientific Research and Development Works is the 2nd Research area – HEALTH. The most serious health threat for the population in Poland includes civilization diseases such as, inter alia, primary as well as secondary degenerative lesions, i.e. those resulting from previous disorders of joint mechanics on the basis of childhood diseases or mobile organ injuries. An increase in the number of joint endoprostheses implanted is connected with progressive ageing of the population, as the percentage of degenerative lesions is the largest among persons above 65 years of age. Apart from ageing of the population, the main cause of most of the diseases of the bone and joint system are hazards resulting from the change in the human environment and unfavorable lifestyle trends. A rapid progress of knowledge makes it possible to get to know civilization diseases better, identify high risk groups, address intervention activities properly and detect diseases earlier, which improves the treatment effectiveness. A significant element of the project includes biotribological tests and acquaintance with the mechanism of mutual influence of individual elements of the endoprostheses. The significance of the project lies in its innovative nature, which involves the fact that intervertebral disc implants constitute a new invasive method of treatment of spine diseases. The invasive method of treatment of spine diseases (an intervertebral disc endoprosthesis) has been applied quite recently. In Poland this method is rarely used despite high social demand for treatment of such types of diseases. This work allows creating fully functional implants. The prototypes will be subject to any tests (in accordance with the EU guidelines) that will specify, whether a given product complies with the requirements for medical devices. The project contributes to a development of collaboration with a local manufacturers of implants and medical devices. The realization of the project will contribute to a development and potential implementation of the method of treatment of spine diseases on a local scale with the use of the solution proposed by INOP. A significant activity includes strengthening of the position of Polish research centers as regards works on designing of human joint endoprostheses, which will also be reflected in the inspiration for development of new patents. The realized project constitutes a platform for establishment of a close collaboration with manufacturers of endoprostheses and medical community. The project will contribute to introduction of a new and competitive product into the market and formulation of a business policy based on identification of market and social demands as regards the improvement of human functions in the society and vocational and physical activities. Economic aspects are also significant, because, as the literature analysis has shown, due to the fact that spine diseases affect young people more and more often and eliminate them from active vocational life, the problem of spine diseases is not only a social issue, but also a general national economic problem. The main advantage for the Metal Forming Institute is the opportunity to prepare and implement the method of treatment of spine diseases on a local scale. The project also allow an improvement and extension of activities of the Institute towards the scientific research works on joint endoprostheses initiated in 2004. A significant solution of the collaboration oriented at the use of results of the project in practice for a new medical device may also be international markets. This activity is oriented at the western markets and countries of the Eastern Europe. A significant orientation includes crisis-affected countries due to the economic aspect and the fact that the project will contribute to a more favorable economic balance of the proposed solution as compared to the presently used solutions. The project results attract companies of the medical sector having a developed distribution network and scientific and research facilities (construction and technology back-up facilities and state-of-the-art laboratories) able to create and absorb innovations of the greatest growth potential and export capabilities. The companies are strictly connected with the medical community, scientific and research institutions and they actively participate in the implementation of the results of the realized projects. As regards the increasing competitiveness, the interested companies, above all, had to prepare personnel responsible for the realization of tasks in all stages of the management. One of the forms of establishment of collaboration oriented at the use of the project results in economic practice or other activities is the promotion of the project. The promotion of technology is mainly addressed to enterprises of the orthopaedic sector to an interested group of practitioners. A significant aspect of the promotion of the realized works is the dynamically developing Polish market. INOP prepared a long-term program connected with the promotion of the project results. The promotion involves the use of the following: the Internet platform (website), promotional events (fairs, international and local conferences, seminars, conferences – congresses with panel discussions, target workshops, Delphi methods and scenarios), a newsletter, educational and training materials (online, e-learning, study visits, debates) as well as a commencement of a debate relating to the project in light of the presented test results. The Center for Excellence of the Metal Forming Institute organizes workshops and trainings for representatives connected with the said issues of the project. The information about the project has been put on the Institute website. The tests results were promoted and propagated and collaboration with entrepreneurs was established during the International Fair in Poznan and at the booth of the INOP Center for Excellence. Literature

|

| Legal notice |

|

| Related papers |

Presentation: Poster at Nano and Advanced Materials Workshop and Fair, by Adrian MrózSee On-line Journal of Nano and Advanced Materials Workshop and Fair Submitted: 2013-06-28 13:17 Revised: 2013-06-28 14:27 |