| Search for content and authors |

Examination of parameters of friction and wear for different mutual position of endoprosthesis elements |

| Adrian Mróz 1, Waldemar Woźniak 2 |

|

1. Instytut Obróbki Plastycznej (INOP), ul.Jana PawłaII14, Poznań 61-139, Poland |

| Abstract |

| Full title of the project: Examination of parameters of friction and wear for different mutual position of endoprosthesis elements Name of the program: Development Project of the 10th Competition Application year: 2009 Realization years: 2010-2013 The list of key parameters of the project: Metal Forming Institute, Poznan University of Medical Science The advanced process of hip joint destruction in history of numerous diseases can be treated effectively with the use of hip replacement procedure. The procedure involves resection of the damaged elements of the joint (articular cartilage and subchondral bone) and replacement of the same with an artificial hip joint – endoprosthesis. The endoprosthesis is to assume functions of the damaged joint and release the patient from pain. Presently, manufacturers of endoprostheses focus on production of implants for even younger and more active patients. In recent years we have observed growing interest in surface endoprostheses characterised by very little bone resection during implantation. The use of the “metal-on-metal” (MoM) couple with large diameters of the head and cup is characterized by an increased scope of mobility and reduces the probability of dislocation. The use of endoprostheses with MoM couple has a favorable influence upon the extension of the implant life as compared to a metal-on-polyethylene couple (MoP), ceramics-on-polyethylene (CoP). A significant problem still includes wear products generated resulting from the use of the endoprosthesis as well as metal ions released in the human body. One of the relevant problems of contemporary hip replacement procedures involves the influence of the setting axis of endoprosthesis components on the friction resistances and their wear mechanisms. The works realized in the Metal Forming Institute aimed at determination of the angle values of mutual position of the “head-cup” couple, for which endoprosthesis functions are characterized by the most favorable tribological parameters. The determination of the optimum ranges of mutual position of endoprosthesis components will contribute to the improvement of computer navigation systems aiding implantation procedures of such types of endoprostheses. The clinical part of the project included tests performed with the use of computed tomography (CT) of hip joints in a group of patients who have had a surface endoprosthesis implanted. CT tests aimed at a determination of average and extreme angle values of position of the endoprosthesis components in relation to the actual axis and rotation of the limb. The analysis of results allowed a determination of nine locations of the head-cup couple that were reconstructed during friction and wear tests. The implant stem angle of the head (45o + 90o) and cup inclination angle (45o) were assumed as fixed. However, the angle of antetorsion of the head (-5o, 10o +25o) and anteversion of the cup (-10o, +20o, +30o) were subject to changes (fig. 1). In order to determine the concentration of Co2+ and Cr3+ions, blood samples were collected from the tested patients.

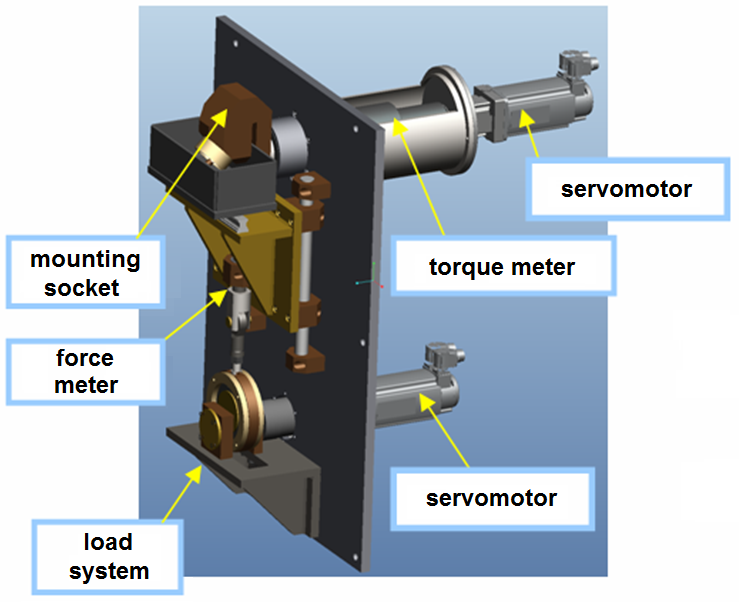

Fig. 1. The angle of anteversion of the cup and antetorsion of the head in relation to the system of anatomical planes: a) three basic anatomical planes [1], b) artificial hip joint (view from the top) [aofoundation.org] Upon determination of the angle values of locations of endoprostheses components, friction and wear tests were performed with the use of a simulator of hip endoprostheses (Fig. 2), the structure of which was prepared in INOP. The structure was based upon the anatomical structure of the human hip joint. It enables a measurement of the friction resistances with a possible modification of geometry of mutual position of the head-cup couple. Moreover, the simulator was designed to enable sampling of wear products generated as a result of friction for the purposes of further analyses. Covering of the metal elements of the simulator with a fluoropolymer coating made enabled determining of the concentration of metal ions released into the lubricating fluid during the realization of the friction and wear tests.

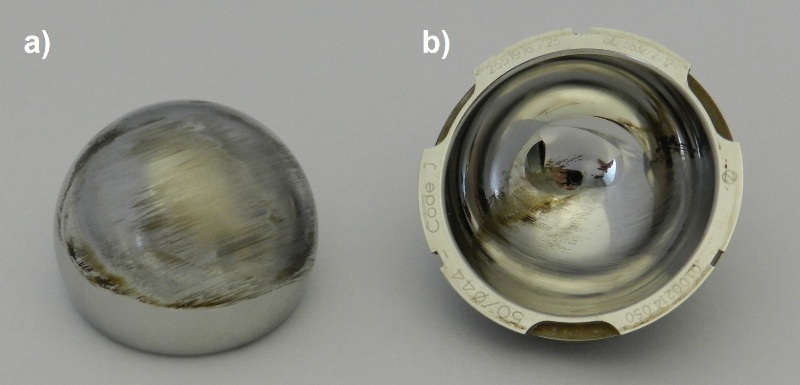

Fig. 2. A simulator of the hip joint SBT-01.1 [2] The object of the friction and wear tests included nine sets of MoM type hip endoprostheses with Ø44 mm diameter of the cup and head. The endoprostheses were made of an alloy based on cobalt (Metasul, ISO 5832-12). Each of the endoprostheses worked for 1 000 000 cycles in the simulator, which corresponded to approx. one year of use in in-vivo conditions. The friction loop was loaded with a force of maximum instantaneous value of 1300 N. The range of bending/strengthening movements was 40owith the frequency of 1 Hz. The tests were conducted in the distilled ultraclean water environment. Each test was performed for different mutual position of the “head-cup” couple elements [3]. The friction coefficient value was calculated on the basis of measurements of the friction moment. All components of the tested endoprostheses were weighed and measured with respect to roughness before commencement and after completion of the friction and wear tests. The analyses of the concentration of Co2+ and Cr3+ ions in the lubricating fluid were made with the use of the method of atomic absorption spectrometry. The analysis of the obtained test results and definition of correlations between the friction coefficient, changes of roughness of friction surfaces, mass wear and concentration of metal ions in the lubricating fluid in relation to the geometry of mutual position of the head-cup couple contributed to the creation of a unique relative database. Apart from the possibilities of visualization of the data collected, the database was equipped with a tool, enabling forecasting of the values of friction resistances, wear and level of concentration of metal ions depending on the mutual position of the endoprosthesis components. Further scientific and research works will include numerical simulations aimed at determining of the influence of the mutual position of the head-cup couple upon values of reduced stresses existing in the friction loop and at the boundary of the implant-bone couple. The test results obtained so far confirmed the assumption that the angle of mutual position of hip endoprosthesis components has a significant influence upon the values of the friction resistances and, consequently, the intensity of the wear of endoprosthesis, which influences their life. Depending on the change of position of the head in relation to the cup or the cup in relation to the head, an average value of friction coefficient (for results recorded every 100 000 cycles worked) changed from 0.139 to 0.231. The friction processes resulted in an increase of roughness of the friction surfaces and a decrease of mass of the endoprothesis elements cooperating with one another. The measurements showed that cups were characterized with a greater mass wear. The roughness parameter of friction surfaces upon completion of tribological tests was within the range of 0.51 µm to 0.85 µm for the heads and from 0.54 µm to 1.13 µm for the cups. The mass decrease fell within the range of 29.8 mg to 97.8 mg for the heads and from 179.1 mg to 316.6 mg [3]. The condition of friction surfaces upon the completion of the friction and wear tests is presented in Fig. 3.  Fig. 3. An example of the condition of friction surfaces of the endoprosthesis upon completion of the friction and wear tests: a) head, b) acetabulum cup Fig. 3. An example of the condition of friction surfaces of the endoprosthesis upon completion of the friction and wear tests: a) head, b) acetabulum cup

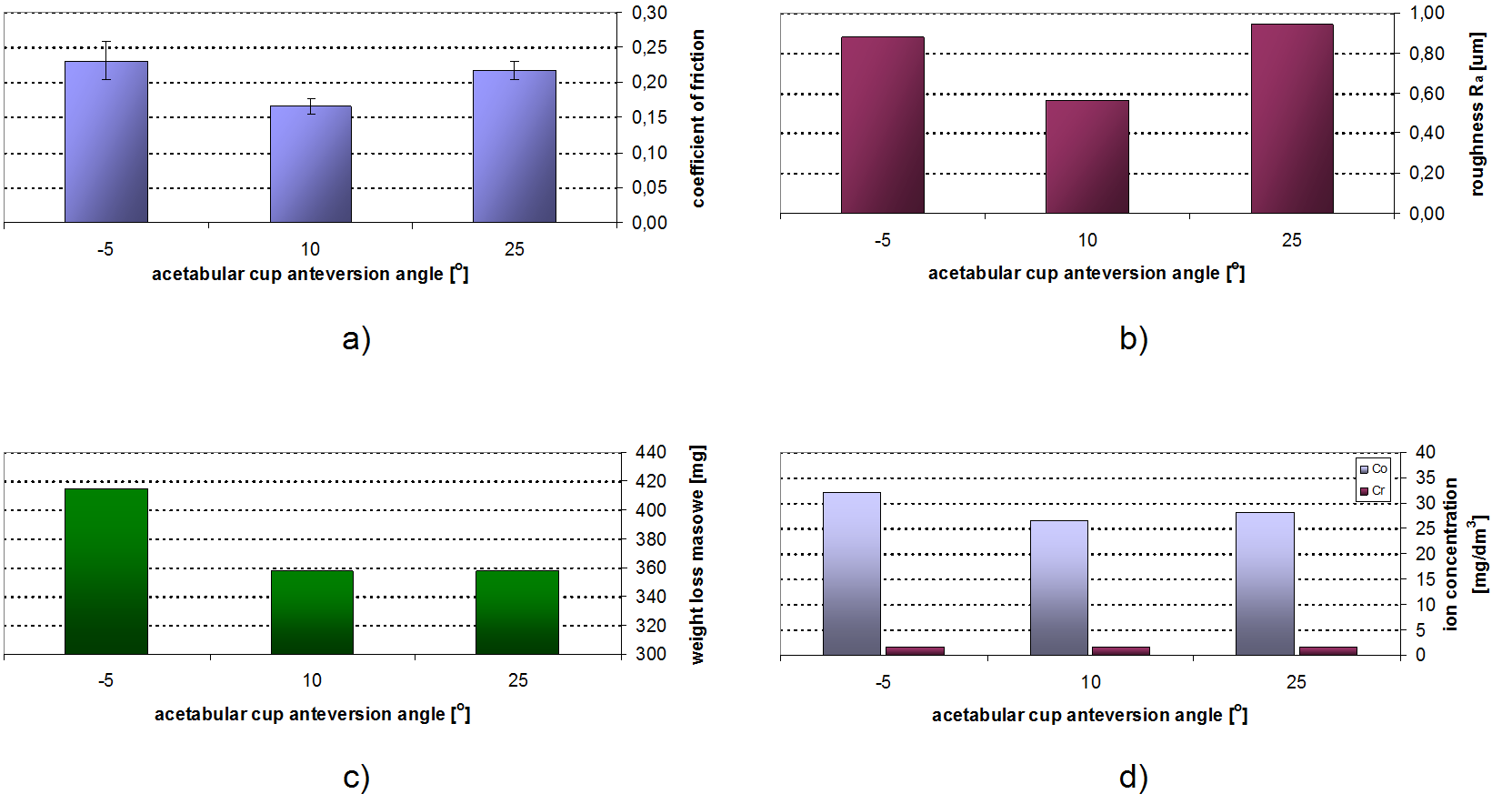

The analysis of concentration of cobalt and chrome ions in the lubricating fluid showed that their concentrations were much too high than in the clinical samples. Depending on the mutual position of the head-cup couple elements, the concentration of Co2+ ions changed from 17.2 to 31.5 mg/dm3 and Cr3+ from 0.14 to 1.64 mg/dm3, whereas the clinical samples showed from 1.01 to 7.39 µg/dm3 Co2+ ions and from 0.32 µg/dm3 to 3.90 µg/dm3 Cr3+ ions. Figure 4 shows the results of the calculations of the friction coefficient, the Ra roughness measurements, mass wear and concentration of Co2+ and Cr3+ ions in the lubricating fluid for three randomly selected positions of the head in relation to the cup. The results show unambiguously that the change of the angle of the cup position (angle of anteversion: -5o, +10o, +25o) in relation to the head (angle of antetorsion equaling 10o) has an influence upon the values of the friction resistances. Decreases or increases of the values of the angle of cup anteversion in relation to the initial position (20o) led to an increase of the value of the friction coefficient (Fig. 4a). Greater friction resistances led to the intensification of the wear processes, which was manifested in increases of the roughness (fig. 4b) and mass wear (fig. 4c) of the friction components. The greater intensity of the wear processes was also reflected in an increase of the concentration of metal ions in the lubricating fluid (fig. 4d).  Fig. 4. Influence of the angle of cup anteversion upon: a) friction coefficient, b) roughness of friction surfaces, c) mass wear, d) concentration of ions in the lubricating fluid Fig. 4. Influence of the angle of cup anteversion upon: a) friction coefficient, b) roughness of friction surfaces, c) mass wear, d) concentration of ions in the lubricating fluid

Finding and defining of the correlations between the tested physical values depending on the mutual position of the head-cup couple elements constituted an inspiration for designing and delivery of a relative database. Next, a platform was developed as connected directly with the database. Apart from the functions involving graphic and user-friendly method of presentation of the collected clinical and laboratory test results, the platform was equipped with a special tool that enables forecasting the values of friction resistances, wear consequences as well as the levels of concentration of Co2+ and Cr3+ ions depending on the mutual position of the hip endoprosthesis elements. Owing to this unique tool, an orthopaedist will be able to make a correction in his suggested position of the “head-cup” couple elements at the very stage of preoperative procedures. It will be sufficient to introduce angles ranges of position and the tool will search for and suggest the optimum position (fig. 5). A serious health threat for the population in Poland includes civilization diseases such as, inter alia, primary as well as secondary degenerative lesions, i.e. resulting from previous disorders of joint mechanics on the basis of childhood diseases or mobile organ injuries. An increase in the number of joint endoprostheses implanted is connected with progressive ageing of the population, as the percentage of degenerative lesions is the largest among people above 65 years of age. Apart from the ageing of the population, the main cause of the majority of bone and joint system diseases are hazards resulting from changing of the human environment and a sitting lifestyle. A rapid progress of knowledge makes it possible to get to know civilization diseases better, identify high risk groups, address intervention activities properly and detect diseases earlier, which improves treatment effectiveness.

Fig. 5. A browser of optimum parameters of mutual position of the hip endoprosthesis elements– a screenshot A significant element of the project includes biotribological tests and acquaintance with the mechanism of mutual influence of individual implant elements. The most comfortable method of obtaining information related to this issue is the correlation between clinical observations and an analysis of the issue from the point of view of biomechanical structure of the human organism. One of the tasks of the project entitled “Examination of parameters of friction and wear for different mutual position of endoprosthesis elements” is the structure of a physical model of the human hip joint implant elements. The analysis of suboptimum mutual position of the endoprosthesis elements is aimed at an improvement of the comfort of life of patients with a hip endoprosthesis implanted by increasing the reliability of the implants and, consequently, decreasing the risk of revision procedures. The Innovative Economy programmed imposes an implementation of new materials and technologies, extension of specializations by new applications and products oriented at new markers in accordance with the propriety axis 1. PO IG:

Thus, the project correlates with the strategy of development of science in Poland until 2015 and the National Program of Research and Development Works in the 2nd research area: Health and 4th research area “Modern technologies for economy”. A relevant prerequisite for undertaking of this Project is global development of new technologies of horizontal character that are significant for modern systems of social security and health protection. The Project also shows a full correlation with the Regional Innovation Strategy entitled “INNOVATIVE WIELKOPOLSKA”. The vision in the document is the province of Wielkopolska (Greater Poland):

Finally, it should be stressed that the realized Project directly fulfills one of the strategic aims of the Regional Strategy of Development i.e. the use of the research potential of the province of Wielkopolska for protection of health and increase of comfort of living for its society. Literature

|

| Legal notice |

|

| Related papers |

Presentation: Poster at Nano and Advanced Materials Workshop and Fair, by Adrian MrózSee On-line Journal of Nano and Advanced Materials Workshop and Fair Submitted: 2013-06-28 09:36 Revised: 2013-06-28 14:14 |