| Search for content and authors |

Study of thermal stratification in EM force driven turbulent flow in square-shaped crucible for directional solidification method |

| Vadims Geza 1,2, Bernard Nacke 1, Egbert Baake 1, Andris Jakovics 2 |

|

1. Leibniz Universitaet Hannover, Institute of Electrotechnology (ETP), Wilhelm-Busch-Str. 4, Hannover 30167, Germany |

| Abstract |

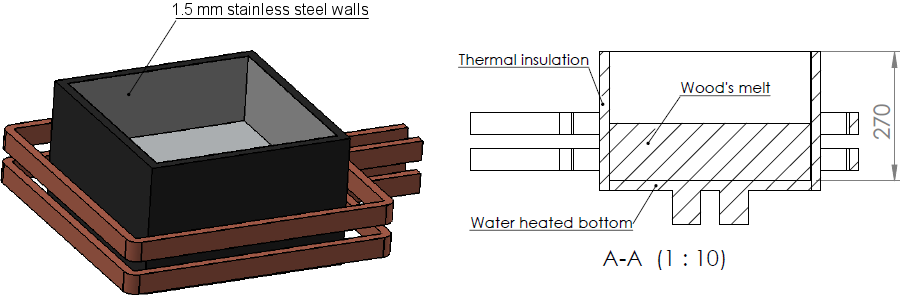

| As fossil energy resources are getting exhausted, demand for alternative energy sources is growing. For example, in 2011 in Germany the renewable energy part was 12.5%, and it is almost doubled during last 6 years [1]. Directional solidification (DS) is widely used for the production of photovoltaic materials in crucibles, usually square-shaped for convenient and material-loss effective wafer production. These ingots are produced in different sizes which are still growing to fit growing demand for solar cells. The quality of such ingot depends primarily on the feedstock. However, the success of each production step, two of which – melting and solidification – include the liquid phase, is also crucial for such parameters as polycrystalline grain size, concentration of incorporation, dislocation and other defects. Understanding and controlling of the melt flow during solidification phase is important for the reduction of N, C and O incorporations and precipitation formations [2], [3], [4]. This study is devoted to the numerical and experimental investigation of the turbulent melt motion in a square crucible where the flow is created by Lorentz forces generated by external AC magnetic field through. As a strong vertical thermal gradient is present in DS method in melt, stratification effect takes place and motion in vertical direction is damped by buoyancy forces. Geverning processes Incompressible fluid flow is described by Navier-Stokes equation, which in dimensionless form includes few parameters - Reynolds number Re, electromagnetic interaction parameter F0, Richardson number Ri. All these parameters define the flow regime. The Richardson number is a ratio of buoyancy forces to inertial forces. In case of Ri below unity, the inertial forces dominate and buoyancy forces are not sufficient to prevent turbulent mixing. In the opposite case, Ri much above unity, buoyancy damps the turbulent pulsations in z directions. Typical Ri for directional solidification devices is of the order of magnitude 10. Numerical research of melt motion problem in crucible implies the solution of fluid flow and heat transfer, and electromagnetic (EM) equations when EM stirring is present. However, if the flow is turbulent, a modelling approach has to be used to obtain solution in reasonable time – DNS method, which resolves all turbulent scales down to Kolmogorov scales, is very time and resource demanding and is not able to solve turbulent for high Reynolds numbers. Two most well known approaches for turbulence modelling are Reynolds Averaged Navier-Stokes (RANS) and Large Eddy Simulation (LES), widely used also in modelling of melt flow in DS method. The numerical results show that turbulent heat flux in vertical direction in overestimated in RANS models, especially at high Ri numbers. The main reason for this is assumption of isotropic turbulence. However, LES models with significant spatial resolution is able to capture anisotropy effect.Experimental Measurements Physical model experimental device (Figure 1) was built, using eutectic Wood's alloy (50% Bi, 25% Pb, 12.5% Sn, 12.5% Cd, melting temperature 72°C) as working liquid. The set-up consists of square-shaped crucible with side length 420 mm, and height 270 mm, filled with Wood's alloy to level H=120mm. The crucible has stainless steel walls with thickness 1.5 mm. The crucible is placed on water heated (T=80°C) aluminium plate. The radiation heater is used as lid on the crucible, which allows achieving vertical temperature gradient in the alloy. However, the emissivity of the Wood's alloy is very low (~0.15) and therefore radiative heat flux on the free surface is low, thus major heat flux on the free surface is ensured by the heated air in the space between alloy and lid. In this set-up steady temperature difference between top and bottom surface up to 80°C was obtained without EM mixing.

Fig 1. Sketch of experimental set-up. Left - 3D view. Right - vertical middle cross section. Ultrasound Doppler Velocimetry (UDV) allows to measure the velocity profile along the ultrasound beam and is able to obtain signal even through wall [5]. For this reason UDV technique (device Signal Processing DOP 3000) was chosen for current set-up. Vertical temperature profile was measured with 6 thermocouples with vertical spacing 20 mm starting from 10 mm above bottom.

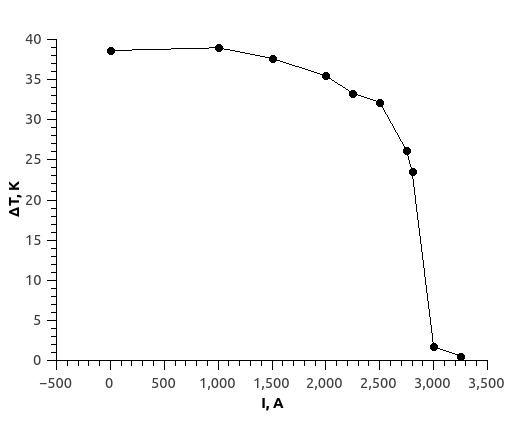

Fig 2. Vertical temperature gradient dependence on total inductor current. The important effect of stratification is the damping of vertical motion including vertical turbulent pulsations. Figure 2 shows vertical temperature difference in dependence on total current I in the inductors. In developed turbulent regime Ri~1/I2 dependence is expected. Then it is also clear, that some critical current ICR exists, when Ri becomes smaller than unity and turbulent mixing prevail, thus change of flow structure is possible. Slight decrease of vertical temperature difference with growth of I which is observed also below ICR (0-2,500A), this can be explained with increase of turbulent pulsations and thus turbulent heat conductivity. At the ICR vertical temperature displacement due to turbulence become so large that fluid particle displaced from thermal equilibrium buoyancy forces are unable to return to initial level. Here flow structure changes from stratified quasi-two dimensional layered structure to three dimensional. Summary In current work numerical models in case of stratified EM driven flow were tested and compared with experimental results, which are obtained with physical model. Existing physical model allows to measure velocity and temperature field in stratified flows. Using obtained results, main features of stratified flows were obtained, including two dimensionality of mean flow and damping of vertical turbulent pulsations. References [1] D. Bohme. Entwicklung der erneuerbaren Energien in Deutschland im Jahr 2011. http://www.erneuerbare-energien.de. [2] C. Reimann, M. Trempa, T. Jung, J. Friedrich, G. Muller. Journal of Crystal Growth.(2010) Vol 312. pp. 878. [3] H.J. Moller, L. Long, M. Werner, D. Yang. Phys. Stat. Sol. (1999) Vol 171. pp. 175. [4] G. Du, N. Chen, P. Rossetto. Sol. Energy Mater. Sol. Cells (2008) Vol 92. pp. 1059. [5] S. Eckert , G. Gerbeth. Experiments in Fluids 32 (2002) 5, p. 542-546 |

| Legal notice |

|

Presentation: Oral at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, Topical Session 8, by Vadims GezaSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-04-12 11:33 Revised: 2013-04-12 16:10 |