| Search for content and authors |

Cooling-Rate-Controlled Rapid-Melting-Growth for Giant-Single-Crystal SiGe on Insulator |

| Ryo Matsumura , Ryusuke Kato , Yuki Tojo , Taizoh Sadoh , Masanobu Miyao |

|

Kyushu University, Fukuoka, Japan |

| Abstract |

1. Introduction To break through the scaling limit of LSIs, multi-functional devices should be integrated on Si platform. SiGe-on-insulator (SGOI) structures are essential for this purpose. They provides advanced channels for high-speed transistors. In addition, SiGe are ideal epitaxial template for various optical- and spintronic-materials with different lattice constants. Recently, we proposed the Si-seeded rapid-melting growth (RMG) of a-SiGe [1,2] and realized laterally graded SiGe on insulator (SGOI) [3]. To expand the application fields, SGOI with uniform Si concentration profile should be developed. In this study, rapid-melting growth of SiGe is investigated with seed-free processing. Large SGOI with uniform Si concentration through segregation-free RMG is realized by optimizing the cooling rate.

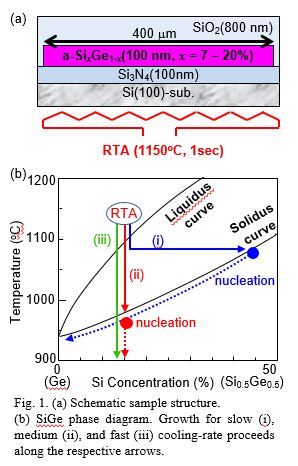

2. Experimental Procedure Si(100) wafers covered with Si3N4 films were employed. After a-SixGe1-x (0.07 < x < 0.2) films (thickness: 100 nm) were deposited, the SiGe films were patterned into strips (width: 5 mm, length: 400 mm). After deposition of SiO2 capping layers (thickness: 800 nm), the samples were heat-treated by RTA (1150oC, 1 sec) [Fig.1(a)]. The cooling rate after RTA was controlled in a wide range of 2-17oC/sec. As shown in Fig.1(b), for the slow cooling rate (i), Si-rich nuclei will be generated in the molten region, when the temperature approaches the solidus curve. Growth initiated at the nuclei follows the solidus curve, which results in SiGe segregation. However, for the fast cooling rate (iii), nucleation occurs at temperatures far below the solidus curve. This is because incubation time for nucleation cannot be secured above the solidus curve. Such super cooling will result in poly-crystallization without segregation. On the other hand, for the medium cooling rate (iii), the nucleation will occur at temperatures in the vicinity of the solidus curve. Such “mild” super cooling will generate a limited number of nuclei and thus, result in a large single-crystal SiGe without segregation.

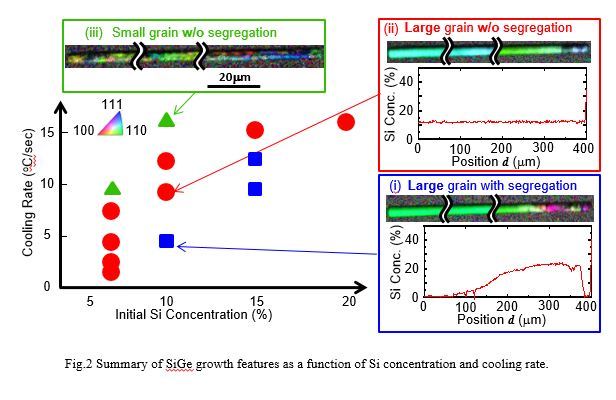

3. Results and Discussion Growth features of samples with various initial Si concentrations grown under various cooling rates are summarized in Fig.2. Typical EBSD images and Si concentration profiles for Si0.1Ge0.9 samples are also shown in Fig. 2. As we expected, for the fast cooling (triangles), the EBSD image indicates poly-crystallization (grain size: 5-10 μm). For the slow cooling (squares), the EBSD image indicates formation of a giant crystal grain (~400 mm). However, the Si concentration shows a laterally graded profile indicating segregation during melt-back process [3]. Interestingly, a large SiGe crystal with uniform Si concentration is achieved under medium cooling rate (circles), where the concentration is identical to the initial value. As shown by the circles in Fig.2, giant single-crystal SiGe grains with uniform Si profiles are obtained in a wide range of Si concentrations by selecting the cooling rate.

4. Conclusions Seedless rapid-melting growth of SiGe has been investigated. By controlling the cooling rate, segregation-free giant SGOI is achieved for a wide range of the Si concentrations. These results open up the possibility of integration of advanced functional devices on Si platform.

Reference [1] M.Miyao et al., APEX 2, 045503 (2009). [2] T.Tanaka et al., APEX, 3, 031301 (2010). [3] R.Matsumura et al., APL 101, 241904 (2012). |

| Legal notice |

|

| Related papers |

Presentation: Poster at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, Topical Session 5, by Ryo MatsumuraSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-04-12 06:16 Revised: 2013-04-16 05:08 |