| Search for content and authors |

Ceramic material ZnSe(Te) fabricated by nanopowder technology. Fabrication, phase transformations and photoluminescence. |

| Elena Borisenko , Nikolai Kolesnikov , Dmitrii Borisenko , I. I. Zverkova , Aleksei Tereschenko , Anna Timonina |

|

Institute of Solid State Physics Russian Academy of Sciences, Akademika Osip'yana 2, Chernogolovka 142432, Russian Federation |

| Abstract |

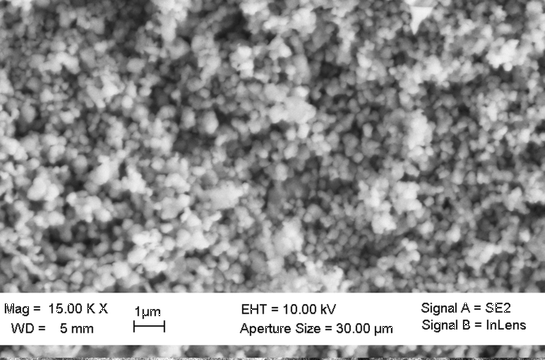

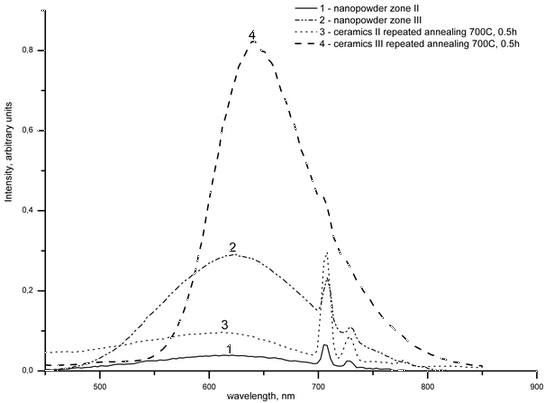

| Zinc selenide is used in optics due to wide transmission range, low absorbtion coefficient. Doping with some activators increases photoluminescence properties of ZnSe crystals [1]. Studies of emitting properties of tellurium doped ZnSe crystals have shown that they can be efficiently used as scintillators in dosimeters and x-ray radiation detectors [2]. It is non-hygroscopic, which is one more advantage for usage in detectors. The most widely used method of production ZnSe and ZnSe(Te) materials is melt growth [1, 3]. This technique requires a complicated equipment to supply the growth process with high pressure of inert gas and to maintain high temperature. A serious drawback of a grown crystal is non-uniform distribution of components along a boule. Among other methods of fabrication of bulk ZnSe and tellurium-doped zinc selenide is recently developed hot pressing [4]. This method provides dense ceramics for optical applications. However, its implementation has some drawbacks: it is attributed to high isostatic pressure and melting temperatures, the fabricated material is carbon contaminated because of usage of protecting foil, and contains traces of lubricants. Production of II-VI ceramics from micropowders by cold compression failed, because of low density of produced materials (no better than 60 % of crystallographic density). Choice of nanopowder as a precursor for ceramic production gives a unique possibility for fabrication of dense ceramics by powder technology. The CdTe and Cd-Zn-Te ceramics (95 % of crystallographic density) produced by cold compaction [5] proves to be less expensive than crystal growth by Bridgman technique, and, contrary to hot isostatic compression, does not entail contamination of the produced ceramics. The produced material is competitive in applications for optic filters and ionizing radiation detectors [6]. That was the reason to develop new ZnSe(Te) ceramics by nanopowder compaction, which we have recently begun [7]. The aim of this work is fabrication of new bulk material, Te-doped ZnSe ceramics and studying of the effect of compaction and heat treatment on its phase composition, structure and luminescent properties. Pure and doped II-VI nanopowders were obtained by vapor deposition on the set up designed in our laboratory [6]. Crumble of ZnSe polycrystal doped with 0.5 at % Te (the precursor purity of the components for crystal growth was ZnSe (99.999 %) and synthesized ZnTe from Zn (99.999 %) and Te(99.9995 %) was put in a plate loaded in the quartz reactor. Nanopartices deposited on cold walls of the quartz reactor. Partly nanoparticles were transported by helium flow and trapped in the bubbler. The deposition zone is conditionally divided into three zones: hot zone III (T = 200ºC), intermediate zone II (100<T<200ºC), cold zone I (T ≤ 100ºC). The nanopowders were compacted on a TT-CM-L Instron machine under pressure 650 MN/m2 at room temperature in a steel matrix of 10-2 m in diameter without bindings or lubricants. X-ray diffraction (XRD) patterns were taken on a Siemens D500 diffractometer under CoKα or CuKα radiation, at the angle range from 20 to 120 degrees. Phase analysis, calculation of unit cell parameter, and estimation of grain size were done using PowderCell (Werner Kraus & Gert Nolze, BAM Berlin). Accuracy of the unit cell measurements was 0.003Å. Photoluminescence (PL) of the nanopowders and ceramics was measured at room temperature. He-Cd laser with the wavelength 325 nm and the pump power 0.5 W/cm2 was used for excitation of PL. Electron probe microanalysis (EPMA) was performed on a Supra 50VP scanning electron microscope (SEM) equipped with INCA Energy+ add-in. Samples were annealed in a furnace separately in sealed tubes under pressure 1.3 N/m2. The samples were put in the furnace at the annealing temperature, which was measured by a chromel-alumel thermocouple. The samples were cooled with the furnace to room temperature at the rate 10-2 deg/s. According to XRD and EPMA data, there are three different nanopowders whose content and phase composition depends on temperature of the deposition zone. Nanopowder from zone I, in which Tdep ≤ 100ºC, consists of 35 vol % of sphalerite and 65 vol % of wurzite. The unit cell parameters of cubic and hexagonal phases are the same as the respective database parameters for pure ZnSe: acub = 5.669Å, F-43m (216) (№ 37-1463 JCPDS), ahex = 3.996Å, chex = 6.55Å, P63mc (186) (№ 15-0105 JCPDS). The XRD data show that the deposited nanopowder from zone I contains no tellurium. The microanalysis data show that Te content in the nanopowder in this case does not exceed 0.5 at %. This agrees with the result of X-ray phase analysis. Grain size estimated by FWHM from X-ray diffraction patterns is 16 nm in the cubic phase and 11 nm in the hexagonal phase. Phase analysis of the nanopowder from zone II shows that the ratio between sphalerite and wurzite is approximately 1:1. Besides, in the zone II nanopowder traces of free Te (№ 36-1452 JCPDS) appear in diffraction patterns. Unit cell parameters of the hexagonal lattice are the same as in the previous case, while the unit cell parameter of the cubic phase calculated from XRD patterns is аcub = 5.671Å. Grain sizes are 26 and 13 nm in the cubic and hexagonal phase, respectively. Nanopowder from hot zone III also consists of cubic and hexagonal phases, but fraction of hexagonal phase decreases as compared with the previous two cases: nanopowders from I and II zones. There is 23 vol % of wurzite and the rest is cubic phase. Grains are coarser than in the previous cases, the nanopowders consist of grains of 35-40 nm. So, it can be concluded from the experiment that the higher the temperature in the deposition zone, the greater is fraction of the cubic phase, and nanopowder grains are coarser, while they size distribution is more homogeneous. Compaction of the nanopowders II and III did not lead to significant changes in phase composition of respective ceramic materials. The ceramics made of tellurium doped ZnSe nanopowder from zones II and III were annealed at Т = 700°С for t = 0.5 h. This treatment brought to phase transition from hexagonal to cubic phase, which was not completed in either of powders. The repeated annealing under the same conditions brought to complete phase transition to the cubic phase in the ceramics III, while in the ceramics II just several percents (~3-5 vol %) of the hexagonal phase remain. The unit cell parameters after the second annealing were аcub = 5.676Å and аcub = 5.680Å for II and III ceramics, respectively. It is known that the ZnSe-ZnTe pseudo-binary system forms a continuous range of solid solutions. According to Vegard law, increase in the unit cell parameter shows formation of ZnSe(Te) solid solution, containing 1.6 and 2.5 at % Te in II and III ceramics, respectively. The results of EPMA show that after double annealing Te enters solid solutions entirely without any loss during annealing. The Te content corresponds to that of nanopowders from respective deposition zones. Figure 1 shows SEM images of microstructure of ceramics III. Average grain size measured from these micrographs is 50 nm, which agrees well with the grain size estimated from the diffraction patterns. Figure 2 shows PL spectra of the ZnSe(Te) nanopowders from zones II and III and the ceramics after annealing. PL spectra of the ZnSe(Te) nanopowders and the ceramics after annealing show that intensity of photoluminescence increases as Te concentration increases. The main peak is at about 625 nm, which is typical for ZnSe(Te) self-activating photoluminescence [8]. Additional lines at 708 nm appear in both nanopowders from II and III zones and weaken in the ceramics III after annealing. According to [8], these lines are associated with selenium vacancies {VSe+}, which probably, disappear during annealing as they are substituted by {TeSe0} in the cubic lattice of the more saturated solid solution. Self-activating PL intensity increases (line 4) after annealing, which may be due to increase in concentration of recombination centers {VZn- + TeSe0}. The results of the experiments allow considering ZnSe(Te) ceramics produced by nanopowder technology as promising materials for dosimeters and scintillating materials in X-ray and gamma ray detectors.  Fig. 1. Microstructure of ZnSe(Te) ceramics  Fig. 2. PL spectra of ZnSe(Te) nanopowders and ceramics REFERENCES [1] W. G. Lee, Y. K. Kim, J. K. Kim, N. Starzhinskiy, V. Ryzhikov, B. Grinyov, Growth and properties of new ZnSe(Al, O, Te) semiconductor scintillator, Radiation Measurements, (2008) v. 43, 502-505; [2] V. D. Ryzhikov, N. Starzhinskiy, L. Gal’chinetskii, P. Gashin, D. Kozin, E. Danshin, IEEE Transaction on Nuclear Science (2001)b, v. 48, 356-359; [3] N. N. Kolesnikov, R. B. James, N. S. Berzigiarova, M. P. Kulakov, HPVB and HPZM shaped growth of CdZnTe, CdSe, and ZnSe crystals, in: R. B. James, L. A. Frank, A Burger, E. M. Westbrook, R. D. Dust (Eds.) Proceeding of SPIE: X-ray and Gamma-ray detectors and Applications IV, San Diego, (2002) v. 4784, 93-104; [4] S. Cool, S. Miller, C. Brecher, H. Lingertat, V. Sarin, K. Riley, S. Mashl, P. Tylus, V. Nagarkar, Fabrication of ZnSe:Te by Hot Pressing Techniques, IEEE Transactions on Nuclear Science, (2010) v. 57 (3), 944-950; [5] N. N. Kolesnikov, E. B. Borisenko, D. N. Borisenko, B. A. Gnesin, Ceramic materials made of CdTe and Cd-Zn-Te nanocrystalline powders, Cent. Eur. J. Chem. (2011), v. 9, (4), 619-623; [6] N. N. Kolesnikov, E. B. Borisenko, V. V. Kveder, D. N. Borisenko, A. V. Timonina, B. A. Gnesin, Semiconductor ceramic materials, in: E. I. Pertsov (Ed.) Nanomaterials: New Research and Development (Nova Science Publishers: New York, 2008); [7] N. N. Kolesnikov, E. B. Borisenko, D. N. Borisenko, I. I. Zverkova, A. V. Timonina, The effect of compaction and heat treatment on phase Transitions of ZnSe(Te) bulk material made of nanopowder, J. of Crystal Growth, (2012), v. 347, 11-14; [8] R. Baltramiejunas, V. D. Ryzhikov, V. Gavryushin, A. Kazlauskas, G. Raciukaitis, V. I. Silin, D. Juodzbalis, V. Stepankevicius, Luminescent and nonlinear spectroscopy of recombination centers in isovalent doped ZnSe:Te crystals, Journal of Luminescence, (1992) v. 52, 71-81. |

| Legal notice |

|

| Related papers |

Presentation: Oral at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, Topical Session 7, by Elena BorisenkoSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-03-29 13:14 Revised: 2013-03-29 14:45 |