| Search for content and authors |

The morphology features of salol crystal growth at the presence of nanoparticles I2O3 |

| Taras Tsir |

|

Physico-Technological Institute of Metals and Alloys, National Academy of Sciences of Ukraine (PTIMA), Vernadsky avenue, 34/1, Kyiv 03680, Ukraine |

| Abstract |

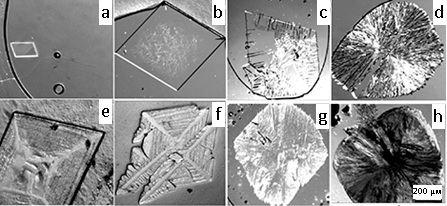

Nowadays it is a widely interest to composites containing nanoparticles. But as it appears from our study nanoparticles can not only play the role as filler agent but affect directly on morphology during solidification. Thus it opens the possibility to make material with structure that impossible to get using conventional methods. In present research impact of nanoparticles of I2O3 (d=20 nm) on the growth of salol crystals under different supercoolings ∆Т (2, 5, 10, 32 0C) was studied. If was found difference as in morphology of crystal growth as in tendency of gas bubbles release from the melt. Fig. 1 shows growth of pure salol Figs. 1а-1d and salol with 10 wt.% nanoparticles Figs. 1e-1h.  Fig. 1. The influence of nanoparticles on the growing structure (a), ( e) ∆Т=2 0С; (b), ( f) ∆Т=5 0С; (c), (g) ∆Т=10 0С; (d), (h) ∆Т=32 0С. Fig. 1. The influence of nanoparticles on the growing structure (a), ( e) ∆Т=2 0С; (b), ( f) ∆Т=5 0С; (c), (g) ∆Т=10 0С; (d), (h) ∆Т=32 0С.

As it can be seen, for pure salol increasing of supercooling resulted in direct transition from faceted Figs. 1a, 1b, 1c to spherulite morphology Fig. 1d. For sample with nanoparticles intermediate (between faceted Fig. 1e and spherulite morphology Fig. 1h) dendrite stage took place Figs. 1f and 1g. Relatively gas bubble release it must be noted that for pure salol intensive emission took place, followed by “classical” capturing – repulsion, Fig. 1c and 1d. For salol with nanoparticles another situation was observed. Gas bubbles appears occasionally, for ΔT < 22 0C its interaction with interface is the same as for pure salol (see captured bubbles, Fig. 1g). For greater supercoolings gas bubble ahead the front “attract” sharp protuberance, Fig. 2a.

Than with the rate, essentially greater than rate of main crystal interface, this protuberance with bubble at the end propagates in the melt by rather arbitrary trajectory, Fig. 2b – 2d. It must be noted, that such behavior was not accidental and observed in all experiments with ΔT >20 0C (Fig. 1h is the stage of growth before meeting with bubble). For pure salol such behavior was not observed in all interval of studied supercoolings. |

| Legal notice |

|

Presentation: Poster at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, General Session 1, by Taras TsirSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-03-29 10:26 Revised: 2013-04-05 11:51 |