| Search for content and authors |

The study of heat transfer processes in the system shaper-melt-crystal in the process of growing massive sapphire profiles by Stepanov/EFG method |

| Roman I. Safronov 1, Yevgeniy Andreev , Leonid Lytvynov |

|

1. Institute for Single Crystals NAS of Ukraine (ISC), 60 Lenin Ave., Kharkov 61001, Ukraine |

| Abstract |

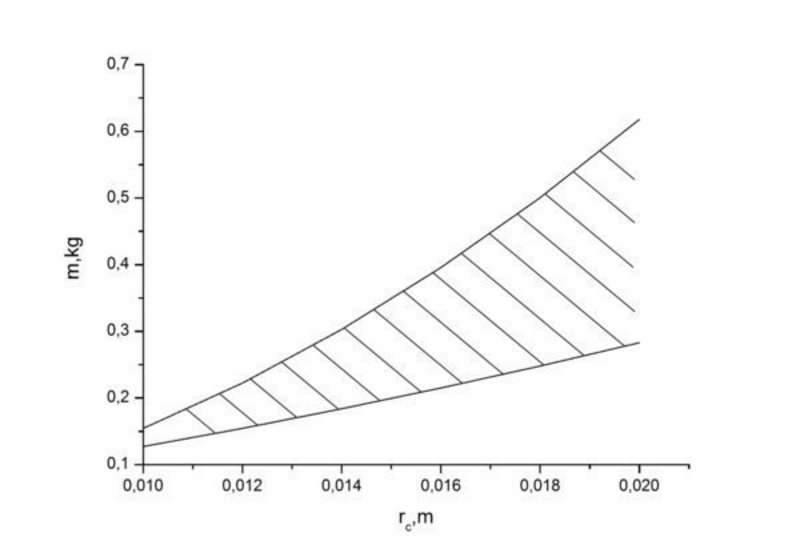

Stability of crystallization front is determined by heat dissipation through the crystal in the process of growing profiled sapphire crystals with large cross sections. Reduction of heat removal from the crystallization front and prevent rejection of the crystal shape from the set is achieved by selection of screens that are installed in the growth zone. The size and weight of the shaper contribute to heat transfer at the crystallization front. The aim of this work is a study of the influence geometric parameters of the shaper on the heat transfer at the crystallization front during the growth of massive profiled sapphire crystals. Heat transfer processconsidered for growing semi-infinite cylindrical sapphire rod in thermal zone with induction or ohmic heating. Capillary system firmly fixed in the crucible and the shaper is a removable cap, which are locatedat the endof the capillary system [1] In the calculations it was assumed that the heat transfer from the crystallization front through the crystal occurs by two mechanisms - the molecular through the shaper and radiation through the crystal. The heat balanceequation on the working surface of the shaper is:Q1(dc,lc,∇T)+Q2(dc,ds,Ts)+Q3(ds,h,Ts,Th)+Q4(ds,Ts,Tcr)=cMoms(Ts-Tc) where: Q1 – heat flux through the growing crystal [2], Q2 – heat flux through the top surface of the base shaper; Q3 – heat flux through the lateral surface of the base shaper; Q4 – heat flux through the film of the melt from the bottom surface of the shaper. ∇T- axial temperature gradient, Th – temperature of the heater, Ts – temperature of the shaper, Tcr – temperature of the crucible, dc – diameter of the crystal, ds – diameter at the base shaper, Ts – temperature of the shaper, СМо – specific heat of the shaper (molybdenum), ms – weight of the shaper. The ranges of the axial temperature gradient, heater temperature, shaper and crucible were set on the basis of experimental data. Calculations have shown that the main parameters affecting the resulting heat flux are: axial temperature gradient, crystal diameter, diameter of the base shaper (its mass) and its temperature. The results of the calculations are shown in the diagram. The shaded area – the area of optimal weights of the shaper.

Fig. Dependent weight of a shaper on diametr of growing the crystall. In the work shows a relationship between cross-sectional area of the crystal, axial temperature gradient and weight of the shaper. The results were used to develop the construction of shaper in the process of growing sapphire rods Ø35 mm and plates 15 х 55 mm optical quality. 1. Andreev Y.P., Lytvynov L.A. Device for growing shaped crystals // Patent of Ukraine № 89883, published in the Bulletin. №5,10,03,2010, in Russian. 2. P. I. Antonov et all. An Experimental and Theoretical Study of Temperature Distribution in Sapphire Crystals Grown From the Melt by Stepanov`s Method // Journal of Crystal Growth. 1980, V. 50, P. 62-68/. |

| Legal notice |

|

| Related papers |

Presentation: Poster at 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17, General Session 2, by Roman I. SafronovSee On-line Journal of 17th International Conference on Crystal Growth and Epitaxy - ICCGE-17 Submitted: 2013-03-25 14:41 Revised: 2013-07-19 19:27 |